HYPO TRAK™

Sodium Hypochlorite Monitoring System

Hypo Trak Brochures

Chem-Scale day tank scale for weighing stationary day tanks. Bulletin 517

IBC Tote-Scale for weighing IBC Tote Bins. Bulletin 517

Drum-Scale for weighing 5 to 55 gallon drums. Bulletin 517

SpillSafe LX containment scale for weighing drums and spill containment. Bulletin 517

Carboy-Scale for weighing drums and carboys. Bulletin 517

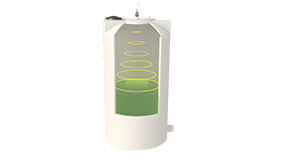

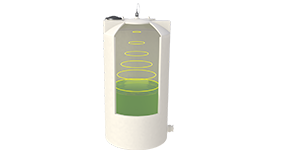

Echo-Scale ultrasonic sensor scale. Bulletin 517

Hypo Trak Technical Specs

| MODEL : | HT-1 |

| INPUT : | Electronic load cell or ultrasonic sensor |

| OUTPUT : | (2) 4-20mA outputs and up to (4) optional relays |

| READOUT SPECS : | 32 character, backlit, alphanumeric LCD |

| NUMERICAL DISPLAY : | 6 full digits (999,999) |

| BAR GRAPH DISPLAY : | User adjustable 0-100% |

| FILTERING : | User adjustable box car averaging |

| DISPLAY UNITS : | lb, kg, gallon, liter. Up to 999,999 |

| INCREMENTS : | 0.1, 0.2, 0.5, 1, 2, 5, 10, 20 or 50 |

| ZERO/TARE ADJUSTMENT : | Via keypad |

| OPERATING TEMPERATURE : | 32-122 Degrees F (0-50 Degrees C) |

| INPUT POWER : | 110-250 VAC (50-60 Hz, 5 watts) or 24VDC |

| CONNECTORS : | 4-20mA & Relays: 1/2” Nylon Conduit Connector Load Cells & Ultrasonic Sensors: 1/2” Nylon Cord Connector |

| ENCLOSURE : | NEMA 4X, UL listed structural foam molded |

| PERFORMANCE : | Overall System Accuracy: 0.1-0.25% F.S., |

| Non-linearity : | <0.03% F.S., Hysteresis: <0.02% F.S., Non-Repeatability: <0.01% |

| F.S., Thermal Stability : | 0.002/Deg F, Zero and Span |

| DATA : | Net Weight, Strength %, Age, 100% CL2 Equivalent, Feed Rate |

| ALARMS : | Pump Vapor Lock, Chlorate Warning, High Level, Low Level |

| RELAYS : | Form C Dry Contact, 2A@30VDC, 0.5A@120VAC |

| CONTACT CLOSURE INPUT : | Disables VAPOR LOCK ALARM when pump intentionally off. Internally pulled up to +5 VDC |

Hypo Trak General Description

Feeding and tracking sodium hypochlorite usage in municipal water treatment systems has presented a challenge for end users for many years. First, sodium hypochlorite degrades over time which makes inventory control and usage documentation very tricky. Secondly, when hypo degrades, it releases gas bubbles that can often get trapped in feed tubing and pumps causing inconsistent feed and in some cases a “vapor lock” of the pump itself. Lastly, as sodium hypochlorite loses strength, it forms byproducts called chlorates. Chlorates are known to impair thyroid function, and therefore regulatory officials are beginning to regulate how much chlorate can be in the water supply, and more specifically, how much chlorate can be contributed to the water supply from the source sodium hypochlorite.

By integrating specialized software with our simple weighing / level display, the Hypo Trak can easily monitor the following:

1) an inconsistent or no feed rate condition via loss in weight (or level) to warn of a vapor locked pump,

2) integrated timers that track how old the hypo is to warn of an excessive chlorate condition,

3) degradation curves that allow you to track your hypo strength over time as it loses strength and

4) conversions that allow you to view & track your hypo in terms of 100% pure chlorine gas to simplify inventory control, PPM calculations, and usage documentation.

The Hypo Trak is compatible with the following Scales/Sensors

Chlor-Scale ton container scale for use with 1 or 2 tanks.

Chlor-Scale 150 for weighing 150 lb cylinders containing chlorine or SO2.

Chem-Scale day tank scale for weighing stationary day tanks.

IBC Tote-Scale for weighing IBC Tote Bins.

Drum-Scale for weighing 5 to 55 gallon drums.

Carboy-Scale for weighing drums and carboys.

SpillSafe LX containment scale for weighing drums and spill containment.

Echo-Scale ultrasonic sensor scale.

Volumetric Feeder Scale for weighing volumetric feeders.

Hypo Trak Typical Written Specs

Hypo Trak Drawings

Hypo Trak Technical Support

For Technical Support, call our FACTORY SERVICE HELP DESK at 1-800-893-6723 (within U.S.) or 925-686-6700.

From the initial writing of a specification through the installation and operation of the equipment, 100% satisfaction is our goal. At FORCE FLOW, we know that a superior customer service and support team is crucial to the success of our customers and the success of our company. Following are some of the services that we offer:

Performance Guarantee

With the purchase of every Force Flow product comes our exclusive Performance Guarantee. If you are unhappy about the performance of one of our products in your chlorination or chemical feed application, you may contact your local distributor and request they begin the restock,refund or exchange process. Under the Performance Guarantee, for 30 days after receiving the product, you may return or exchange it for full purchase price refund or credit towards another Force Flow product. To qualify, all Performance Guarantee refunds or exchanges must be pre-approved by the factory service manager before returning the equipment to the factory.

Warranty WARRANTY STATEMENT.pdf

FORCE FLOW warrants every single one of our products for a period of five years. If a failure occurs within the said period, the warranty extends from the date of FORCE FLOW's shipment, and liability is limited to repayment of the purchase price, repair or replacement of the equipment. All warranty work must be returned to the factory or a center designated by FORCE FLOW.

Service

Our policy is to get all repairs, warranty work and retrofits completed and shipped back to the customer within 48 hours of receiving them at our factory. Trained technicians and a large parts inventory makes this happen. We understand that there is nothing more frustrating than sending something back to the manufacturer and wondering when you will see it again. Two day turnaround—that is our policy! For prompt service, call our FACTORY SERVICE HOTLINE at 1-800-893-6723 (within U.S.) or 925-686-6700.

Technical and Application Support

FORCE FLOW factory engineers have strong technical backgrounds with many years of process weighing experience in both chlorine and chemical feed applications. If you require technical information, application support or help with a custom project, please contact an application engineer at our HELP HOTLINE at 1-800-893-6723.

Hypo Trak Video Demonstration

|

|

Hypo Trak Image Gallery

https://forceflowscales.com/products/indicators/bleach-sodium-hypochlorite-display#sigProIda043e348d4

Hypo Trak Related Items

Related: dual-channel electronic/digital weight indicator