Carboy-Scale with Wizard 4000 Advanced Digital Weight Indicator for weighing portable and stationary drums or carboys.

Bulletin 413

ECHO-SCALE™

Ultrasonic Level Sensors

Echo-Scale Brochures

Echo-Scale Technical Specs

| VESSEL TYPE : | Vertical flat bottom tanks |

| CAPACITY : | Up to 10,000 gallons (4000 liters) |

| RANGE : | Up to 10,000 gallons (4000 liters) |

| TYPICAL APPLICATIONS : | Fluorice * Polymer * Sodium Hypochlorite * Caustic * Alum * Sodium Bisulfate |

Echo-Scale General Description

The Echo-Scale™ is the perfect chemical monitoring solution for large diameter tanks that cannot cost effectively be placed on a scale. Echo-Scale ultrasonic level sensors are ideal for monitoring sodium hypochlorite, fluoride, caustic and all other chemicals stored in bulk tanks or large day tanks at water and wastewater treatment plants.

The Echo-Scale sends out ultrasonic sound bursts to determine the chemical level in the tank. Then through our WIZARD 4000® or SOLO® 1000 indicators, the remaining chemical is displayed as a distance, weight or volume. Special Pulse R™ programming makes the Echo Scale ideal for chemicals that "gas-off" such as sodium hypochlorite. EZ CAL™ software makes set-up and calibration a snap. If local indication is not required, the Echo-Scale operates in "stand alone" mode by sending its 4-20mA signal straight to your computer or PLC.

The PVC/Kynar design of the Echo-Scale makes it extremely durable for use with most chemicals and three models are available to suit tank heights up to 25 feet.

Echo-Scale Typical Written Specs

Echo-Scale Engineered Drawings

Echo-Scale Technical Support

For Technical Support, call our FACTORY SERVICE HELP DESK at 1-800-893-6723 (within U.S.) or 925-686-6700.

From the initial writing of a specification through the installation and operation of the equipment, 100% satisfaction is our goal. At FORCE FLOW, we know that a superior customer service and support team is crucial to the success of our customers and the success of our company. Following are some of the services that we offer:

Performance Guarantee

With the purchase of every Force Flow product comes our exclusive Performance Guarantee. If you are unhappy about the performance of one of our products in your chlorination or chemical feed application, you may contact your local distributor and request they begin the restock,refund or exchange process. Under the Performance Guarantee, for 30 days after receiving the product, you may return or exchange it for full purchase price refund or credit towards another Force Flow product. To qualify, all Performance Guarantee refunds or exchanges must be pre-approved by the factory service manager before returning the equipment to the factory.

Warranty WARRANTY STATEMENT.pdf

FORCE FLOW warrants every single one of our products for a period of five years. If a failure occurs within the said period, the warranty extends from the date of FORCE FLOW's shipment, and liability is limited to repayment of the purchase price, repair or replacement of the equipment. All warranty work must be returned to the factory or a center designated by FORCE FLOW.

Service

Our policy is to get all repairs, warranty work and retrofits completed and shipped back to the customer within 48 hours of receiving them at our factory. Trained technicians and a large parts inventory makes this happen. We understand that there is nothing more frustrating than sending something back to the manufacturer and wondering when you will see it again. Two day turnaround—that is our policy! For prompt service, call our FACTORY SERVICE HOTLINE at 1-800-893-6723 (within U.S.) or 925-686-6700.

Technical and Application Support

FORCE FLOW factory engineers have strong technical backgrounds with many years of process weighing experience in both chlorine and chemical feed applications. If you require technical information, application support or help with a custom project, please contact an application engineer at our HELP HOTLINE at 1-800-893-6723.

Echo-Scale Image Gallery

Ultrasonic Level Sensor

Ultrasonic Level Sensor

Ultrasonic Level Sensor

Ultrasonic Level Sensor

Ultrasonic Level Sensor

Ultrasonic Level Sensor

Ultrasonic Level Sensor

Ultrasonic Level Sensor

Ultrasonic Level Sensor with Wizard 4000

Ultrasonic Level Sensor with Wizard 4000

Ultrasonic Level Sensor with Wizard 4000

Ultrasonic Level Sensor with Wizard 4000

Ultrasonic Level Sensor

Ultrasonic Level Sensor

Ultrasonic Level Sensor

Ultrasonic Level Sensor

https://forceflowscales.com/85-scales?start=12#sigProIdfec0f2f89b

Echo-Scale Related Items

CARBOY SCALE™

For Drums and Carboys

Carboy-Scale Brochures

Carboy-Scale with Solo G2 Dual Channel Digital Weight Indicator for weighing portable and stationary drums or carboys.

Bulletin 413

Carboy-Scale with Solo XT Hydraulic to Digital Weight Indicator for weighing portable and stationary drums or carboys.

Bulletin 514

Carboy-Scale with Century Dial Hydraulic Weight Indicator for weighing portable and stationary drums or carboys.

Bulletin 512

Hi-Accuracy Carboy-Scale with Wizard 4000 Advanced Digital Weight Indicator for weighing portable and stationary drums or carboys.

Bulletin 412

Hi-Accuracy Carboy-Scale with Solo G2 Dual Channel Digital Weight Indicator for weighing portable and stationary drums or carboys.

Bulletin 412

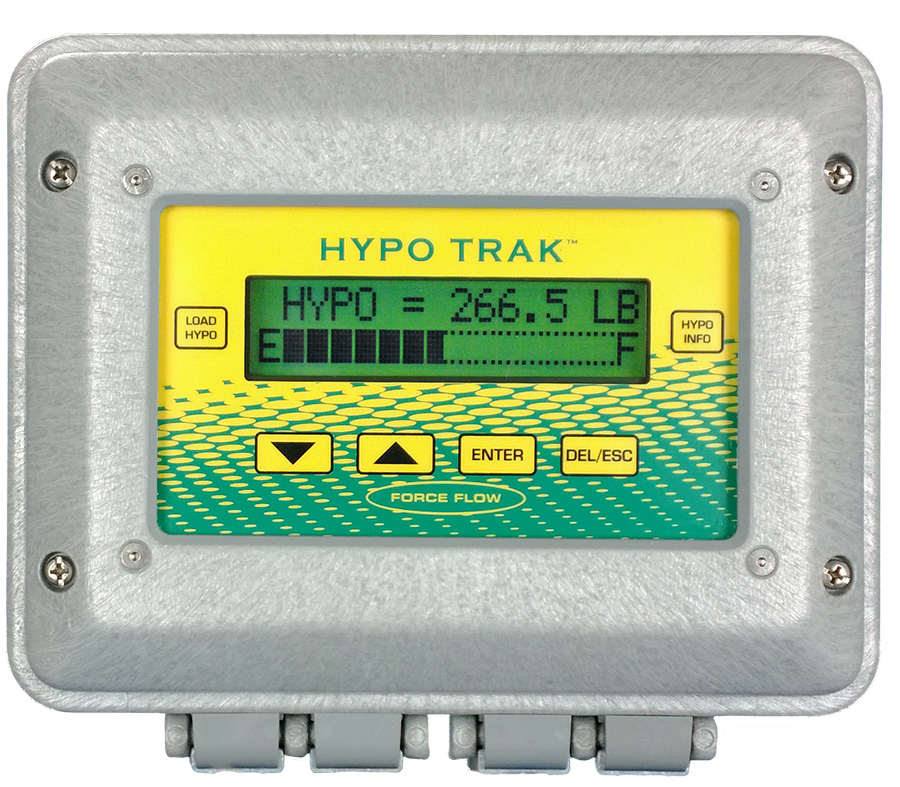

Carboy-Scale with Hypo Trak Indicator for monitoring Sodium Hypochlorite.

Bulletin 517

Carboy-Scale Technical Specs

| VESSEL TYPE : | Portable and Stationary Drums or Carboys |

| CAPACITY : | From 5 to 55 gallons (20 to 200 litres) |

| TYPICAL APPLICATIONS : | Fluoride * Polymer * Sodium Hypochlorite * Caustic * Alum * Sodium Bisulfate |

Carboy-Scale General Description

Under and overdosing of chemicals such as Sodium Hypochlorite and Fluoride can have very serious consequences to consumers of these chemical treated water sources. Because of this, strict Federal and State reporting requirements have created a need for municipal plant operators to easily and accurately track chemical feed rates and usages in water and wastewater treatment plants. Also, by knowing exactly how much chemical remains, plant operators can be assured that the drum will not run empty during their absence.

Our low profile corrosion resistant platforms allow operators to load and unload drum-packaged chemicals safely and easily. Using the DRUMM-SCALE or CARBOY-SCALE for your inventory management results in an inexpensive, non-contacting, highly reliable method of measuring level. Weight (or mass) is an inherently accurate means of measuring vessel contents because it is independent of vessel shape, temperature, and corrosive characteristics of the contents. The DRUMM-SCALE is easily installed by regular plant personnel and with our full 5-year warranty, requires virtually no maintenance.

So be sure to keep your chemical feed system as safe and efficient as possible with a DRUMM-SCALE or CARBOY-SCALE from Force Flow/ Floquip.

The Carboy-Scale is compatible with the following indicators:

Wizard 4000 Advanced Digital Weight Indicator. For use with our electronic scales.

Century Dial Hydraulic Weight Indicator. For use with our hydraulic scales.

Solo XT Hydraulic to Electronic Weight Indicator. For use with our hydraulic scales.

Carboy-Scale Typical Written Specs

Carboy-Scale Engineered Drawings

Carboy-Scale Technical Support

For Technical Support, call our FACTORY SERVICE HELP DESK at 1-800-893-6723 (within U.S.) or 925-686-6700.

From the initial writing of a specification through the installation and operation of the equipment, 100% satisfaction is our goal. At FORCE FLOW, we know that a superior customer service and support team is crucial to the success of our customers and the success of our company. Following are some of the services that we offer:

Performance Guarantee

With the purchase of every Force Flow product comes our exclusive Performance Guarantee. If you are unhappy about the performance of one of our products in your chlorination or chemical feed application, you may contact your local distributor and request they begin the restock,refund or exchange process. Under the Performance Guarantee, for 30 days after receiving the product, you may return or exchange it for full purchase price refund or credit towards another Force Flow product. To qualify, all Performance Guarantee refunds or exchanges must be pre-approved by the factory service manager before returning the equipment to the factory.

Warranty WARRANTY STATEMENT.pdf

FORCE FLOW warrants every single one of our products for a period of five years. If a failure occurs within the said period, the warranty extends from the date of FORCE FLOW's shipment, and liability is limited to repayment of the purchase price, repair or replacement of the equipment. All warranty work must be returned to the factory or a center designated by FORCE FLOW.

Service

Our policy is to get all repairs, warranty work and retrofits completed and shipped back to the customer within 48 hours of receiving them at our factory. Trained technicians and a large parts inventory makes this happen. We understand that there is nothing more frustrating than sending something back to the manufacturer and wondering when you will see it again. Two day turnaround—that is our policy! For prompt service, call our FACTORY SERVICE HOTLINE at 1-800-893-6723 (within U.S.) or 925-686-6700.

Technical and Application Support

FORCE FLOW factory engineers have strong technical backgrounds with many years of process weighing experience in both chlorine and chemical feed applications. If you require technical information, application support or help with a custom project, please contact an application engineer at our HELP HOTLINE at 1-800-893-6723.

Carboy-Scale Image Gallery

Carboy Scale 200

Carboy Scale 200

Carboy Scale 200

Carboy Scale 200

Carboy Scale with Century Dial

Carboy Scale with Century Dial

Carboy Scale with Century Dial

Carboy Scale with Century Dial

Carboy Scale

Carboy Scale

Carboy Scale

Carboy Scale

High Accuracy Carboy Scale

High Accuracy Carboy Scale

High Accuracy Carboy Scale

High Accuracy Carboy Scale

High Accuracy Carboy Scale with Solo G2

High Accuracy Carboy Scale with Solo G2

High Accuracy Carboy Scale with Solo G2

High Accuracy Carboy Scale with Solo G2

https://forceflowscales.com/85-scales?start=12#sigProIdc018067eda

Carboy-Scale Related Items

SpillSafe LX Drum Scale

For 30 to 55 gallon type day tanks

SpillSafe Brochures

SpillSafe LX Technical Specs

| TYPICAL APPLICATIONS : | Fluoride * Polymer * Sodium Hypochlorite * Caustic * Alum * Ammonia |

| DRUM SIZE : | Up to 24” Diameter (typically 55 gallon and smaller) |

| LOAD CAPACITY : | 1000 lbs |

| CONTAINMENT CAPACITY : | SUMP & BLADDER: 66 GALLONS SUMP ONLY: 11 gallons |

| DIMENSIONS (Bladder not deployed) : | 27” x 31” x 6.5" |

| BLADDER DIMENSIONS : | 66” x 58” |

| MATERIAL : | FRAME: 2-Part Epoxy Powder Coated Steel CONTAINMENT VESSEL: Polyethylene (LDPE) ROLL-OUT BLADDER: Polyethylene |

| LOAD CELLS : | (4) Electronic Shear Beam Strain Gauge Type with Polyethylene Protective Splash Shields |

| STANDARD CABLE LENGTH : | 20 ft |

| ACCURACY : | 1/10 of 1% Full Scale |

| COMPATIBLE INDICATORS : | Wizard 4000, SOLO G2, HypoTrak |

| WARRANTY : | 5-YEAR |

SpillSafe General Description

The SpillSafe LX™ Drum Scale monitors chemical usage and remaining inventory while providing total containment in case of a leak or spill. This combined system eliminates the headache of mixing and matching one manufacturer’s scale with another’s secondary containment system.

The SpillSafe™ Drum Scale eliminates the headache of mixing and matching one manufacturer’s scale with another’s secondary containment system. The SpillSafe™ accurately monitors chemical usage data, such as how much has been fed and how much remains, along with providing total chemical containment in case of a leak or spill.

An epoxy powder coated steel platform securely holds the polyethylene spill containment pallet and four IP67 rated shear beam load cells located outside the spill containment vessel provide the highest accuracy weight measurement possible. The load cells are located under the platform and are further protected by removable polyethylene splash guards.

The initial 11 gallons of a leak or spill is contained directly beneath the drum in the polyethylene basin. A replaceable double layer polyethylene roll-out bladder deploys for larger spills and allows total containment of up to 66 gallons while keeping overall scale height at 6 inches for easy drum loading and unloading.

The SpillSafe LX™ Drum Scale comes with the exclusive Force Flow Performance Guarantee™ and 5-Year Warranty to insure your investment continues to meet your chemical monitoring needs.

The SpillSafe LX is compatible with the following indicators:

Wizard 4000 Advanced Digital Weight Indicator. For use with our electronic scales.

SpillSafe Typical Written Specs

SpillSafe Engineered Drawings

SpillSafe LX Technical Support

For Technical Support, call our FACTORY SERVICE HELP DESK at 1-800-893-6723 (within U.S.) or 925-686-6700.

From the initial writing of a specification through the installation and operation of the equipment, 100% satisfaction is our goal. At FORCE FLOW, we know that a superior customer service and support team is crucial to the success of our customers and the success of our company. Following are some of the services that we offer:

Performance Guarantee

With the purchase of every Force Flow product comes our exclusive Performance Guarantee. If you are unhappy about the performance of one of our products in your chlorination or chemical feed application, you may contact your local distributor and request they begin the restock,refund or exchange process. Under the Performance Guarantee, for 30 days after receiving the product, you may return or exchange it for full purchase price refund or credit towards another Force Flow product. To qualify, all Performance Guarantee refunds or exchanges must be pre-approved by the factory service manager before returning the equipment to the factory.

Warranty WARRANTY STATEMENT.pdf

FORCE FLOW warrants every single one of our products for a period of five years. If a failure occurs within the said period, the warranty extends from the date of FORCE FLOW's shipment, and liability is limited to repayment of the purchase price, repair or replacement of the equipment. All warranty work must be returned to the factory or a center designated by FORCE FLOW.

Service

Our policy is to get all repairs, warranty work and retrofits completed and shipped back to the customer within 48 hours of receiving them at our factory. Trained technicians and a large parts inventory makes this happen. We understand that there is nothing more frustrating than sending something back to the manufacturer and wondering when you will see it again. Two day turnaround—that is our policy! For prompt service, call our FACTORY SERVICE HOTLINE at 1-800-893-6723 (within U.S.) or 925-686-6700.

Technical and Application Support

FORCE FLOW factory engineers have strong technical backgrounds with many years of process weighing experience in both chlorine and chemical feed applications. If you require technical information, application support or help with a custom project, please contact an application engineer at our HELP HOTLINE at 1-800-893-6723.

SpillSafe LX Image Gallery

SpillSafe Containment Scale with Bladder

SpillSafe Containment Scale with Bladder

SpillSafe Containment Scale with Bladder

SpillSafe Containment Scale with Bladder

SpillSafe Containment Scale with Drum

SpillSafe Containment Scale with Drum

SpillSafe Containment Scale with Drum

SpillSafe Containment Scale with Drum

https://forceflowscales.com/85-scales?start=12#sigProId69ed9ec6fb

SpillSafe LX Related Items

DRUMM-SCALE™

Drum scales for 30 to 55 gallon drums

Drumm-Scale Brochures

Drum-Scale with Wizard 4000 Advanced Digital Weight Indicator for weighing 30 to 55 gallon drums.

Bulletin 403

Drum-Scale with Solo G2 Dual Channel Digital Weight Indicator for weighing 30 to 55 gallon drums.

Bulletin 403

Drum-Scale with Solo XT Hydraulic to Digital Weight Indicator for weighing 30 to 55 gallon drums.

Bulletin 514

Drum-Scale with Century Dial Hydraulic Weight Indicator for weighing 30 to 55 gallon drums.

Bulletin 205

Drum-Scale with Hypo Trak Indicator for monitoring Sodium Hypochlorite.

Bulletin 517

Drumm-Scale Technical Specs

| VESSEL TYPE : | Portable and Stationary Drums or Carboys |

| CAPACITY : | From 5 to 55 gallons (20 to 200 litres) |

| TYPICAL APPLICATIONS : | Fluoride * Polymer * Sodium Hypochlorite * Caustic * Alum * Sodium Bisulfate |

Drumm-Scale General Description

Under and overdosing of chemicals such as Sodium Hypochlorite and Fluoride can have very serious consequences to consumers of these chemical treated water sources. Because of this, strict Federal and State reporting requirements have created a need for municipal plant operators to easily and accurately track chemical feed rates and usages in water and wastewater treatment plants. Also, by knowing exactly how much chemical remains, plant operators can be assured that the drum will not run empty during their absence.

Our low profile corrosion resistant drum scale platforms allow operators to load and unload 30 gallon drum containers up to 55 gallon drum containers safely and easily. Using a DRUM SCALE or CARBOY SCALE for your inventory management results in an inexpensive, non-contacting, highly reliable method of measuring level. Weight (or mass) is an inherently accurate means of measuring vessel contents because it is independent of vessel shape, temperature, and corrosive characteristics of the contents. DRUM SCALES are easily installed by regular plant personnel and with our full 5-year warranty, requires virtually no maintenance.

So be sure to keep your chemical feed system as safe and efficient as possible with a DRUM SCALE or CARBOY SCALE from Force Flow/ Floquip.

The Drumm-Scale is compatible with the following indicators:

Wizard 4000 Advanced Digital Weight Indicator. For use with our electronic scales.

Century Dial Hydraulic Weight Indicator. For use with our hydraulic scales.

Solo XT Hydraulic to Electronic Weight Indicator. For use with our hydraulic scales.

Drumm-Scale Typical Written Specs

Drumm-Scale Engineered Drawings

Drumm-Scale Technical Support

For Technical Support, call our FACTORY SERVICE HELP DESK at 1-800-893-6723 (within U.S.) or 925-686-6700.

From the initial writing of a specification through the installation and operation of the equipment, 100% satisfaction is our goal. At FORCE FLOW, we know that a superior customer service and support team is crucial to the success of our customers and the success of our company. Following are some of the services that we offer:

Performance Guarantee

With the purchase of every Force Flow product comes our exclusive Performance Guarantee. If you are unhappy about the performance of one of our products in your chlorination or chemical feed application, you may contact your local distributor and request they begin the restock,refund or exchange process. Under the Performance Guarantee, for 30 days after receiving the product, you may return or exchange it for full purchase price refund or credit towards another Force Flow product. To qualify, all Performance Guarantee refunds or exchanges must be pre-approved by the factory service manager before returning the equipment to the factory.

Warranty WARRANTY STATEMENT.pdf

FORCE FLOW warrants every single one of our products for a period of five years. If a failure occurs within the said period, the warranty extends from the date of FORCE FLOW's shipment, and liability is limited to repayment of the purchase price, repair or replacement of the equipment. All warranty work must be returned to the factory or a center designated by FORCE FLOW.

Service

Our policy is to get all repairs, warranty work and retrofits completed and shipped back to the customer within 48 hours of receiving them at our factory. Trained technicians and a large parts inventory makes this happen. We understand that there is nothing more frustrating than sending something back to the manufacturer and wondering when you will see it again. Two day turnaround—that is our policy! For prompt service, call our FACTORY SERVICE HOTLINE at 1-800-893-6723 (within U.S.) or 925-686-6700.

Technical and Application Support

FORCE FLOW factory engineers have strong technical backgrounds with many years of process weighing experience in both chlorine and chemical feed applications. If you require technical information, application support or help with a custom project, please contact an application engineer at our HELP HOTLINE at 1-800-893-6723.

Drumm-Scale Image Gallery

Drum Scale

Drum Scale

Drum Scale

Drum Scale

Drum Scales

Drum Scales

Drum Scales

Drum Scales

Drum Scales

Drum Scales

Drum Scales

Drum Scales

Drum Scale

Drum Scale

Drum Scale

Drum Scale

Polymer Drum Scale

Polymer Drum Scale

Polymer Drum Scale

Polymer Drum Scale

Hydraulic Drum Scales with Century Dial

Hydraulic Drum Scales with Century Dial

Hydraulic Drum Scales with Century Dial

Hydraulic Drum Scales with Century Dial

Hydraulic Drum Scale with Century Dial

Hydraulic Drum Scale with Century Dial

Hydraulic Drum Scale with Century Dial

Hydraulic Drum Scale with Century Dial

Drum Scale in Oil Field

Drum Scale in Oil Field

Drum Scale in Oil Field

Drum Scale in Oil Field

Drum Scale with Wizard 4000

Drum Scale with Wizard 4000

Drum Scale with Wizard 4000

Drum Scale with Wizard 4000

Drum Scale with Wizard 4000

Drum Scale with Wizard 4000

Drum Scale with Wizard 4000

Drum Scale with Wizard 4000

Drum Scale with Wizard 4000

Drum Scale with Wizard 4000

Drum Scale with Wizard 4000

Drum Scale with Wizard 4000

https://forceflowscales.com/85-scales?start=12#sigProId482ee9416f

Drumm-Scale Related Items

|

|

|

|

| Drumm-Scale Platform Clip | Drumm-Scale Ramp | Drumm-Scale Pipe Bracket | |